How we reduced production costs and improved assembly times for Visionplus.

- Visionplus

Sector

- Consumer

Services

- Consumer Design

- Visual Brand Language

- Engineering

- Prototyping

- Design For Manufacture

Project

- Omni Directional Antenna Range

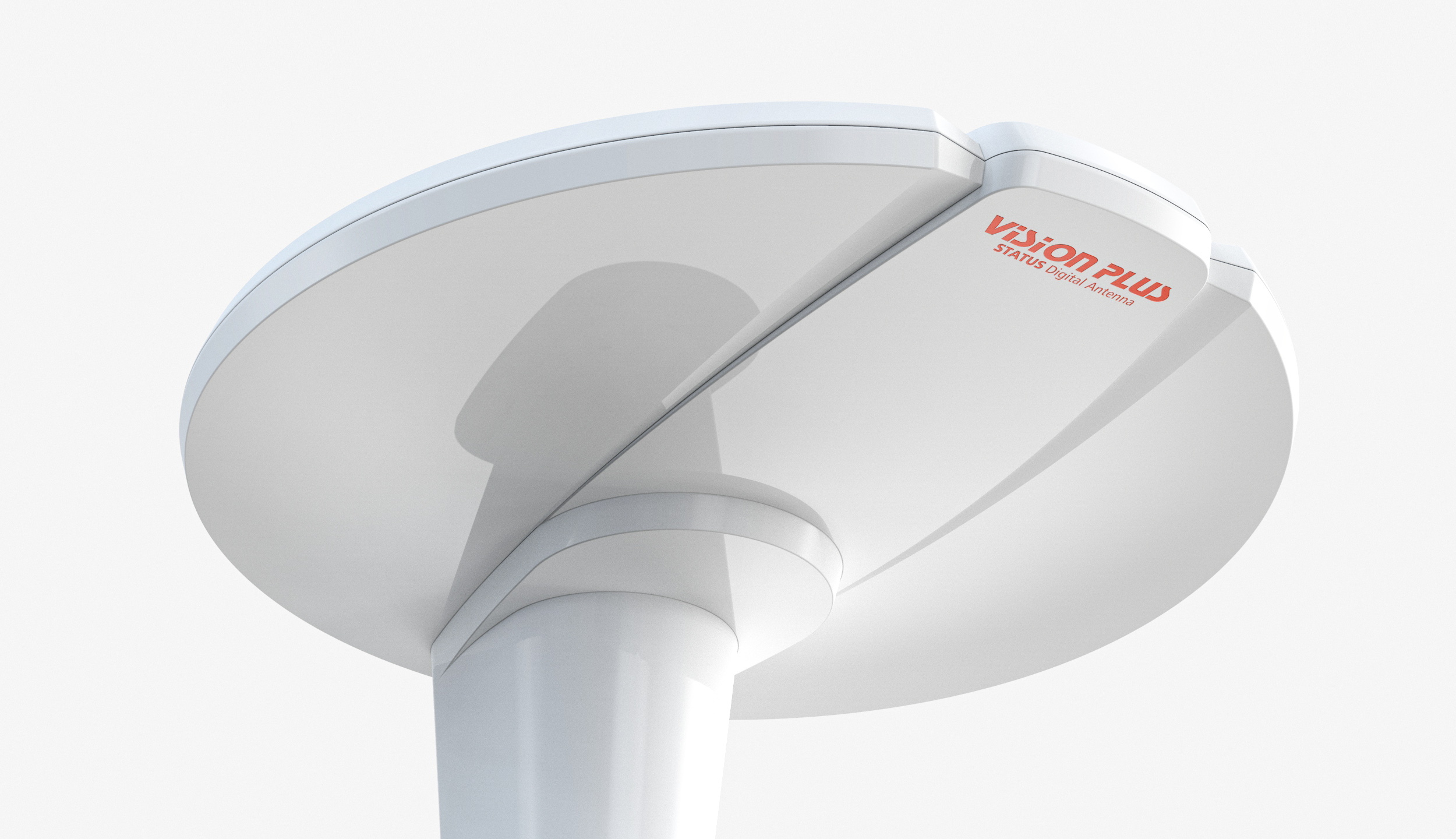

We were asked to redesign 3 new products, delivering an up-to-date coherent design language, resulting in solutions that would be cheaper to manufacture and faster to assemble

Caravans, boats and motor homes use Omni-directional antennas to pick up TV signals. This is because their mobility dictates that the TV signal broadcasted needs to be received from any direction! The electronics in these products amplifies the signal and then distributes it within the caravan, boat or motor home. These antennas are continually exposed to the elements, so strength, longevity and robustness are crucial attributes for product success in the market.

Bluefrog Design asked to redesign 3 new products in the Visionplus antenna range, and deliver an up-to-date coherent design language, resulting in solutions that would be cheaper to manufacture, faster to assemble and capable of withstanding the rigours of the environmental conditions in which they operate.

The Journey

For this project, our consumer product design consultants went through a stringent process to select the best materials to meet the environmental and performance requirements. We carried out extensive FEA (Finite Element Analysis) to test the durability of the products, optimising wall sections for strength, reducing weight and improving aerodynamics. All crucial elements when some motorhomes and caravans are able to travel legally at speeds of up to 60mph.

The Outcome

By using engineering polymers and injection mould tooling we were able to redesign the products as ultra-thin lightweight mouldings, delivering more than a 30% material saving over the existing range – sometimes less is often more. In addition, streamlining the assembly process through the design and manufacture of bespoke fixtures allowed us to use new fastening techniques saving time and money in manufacturing, and significantly improving productivity and quality standards for a class-leading range of antennas.

Related Projects

Ready to talk about your project?

Socials