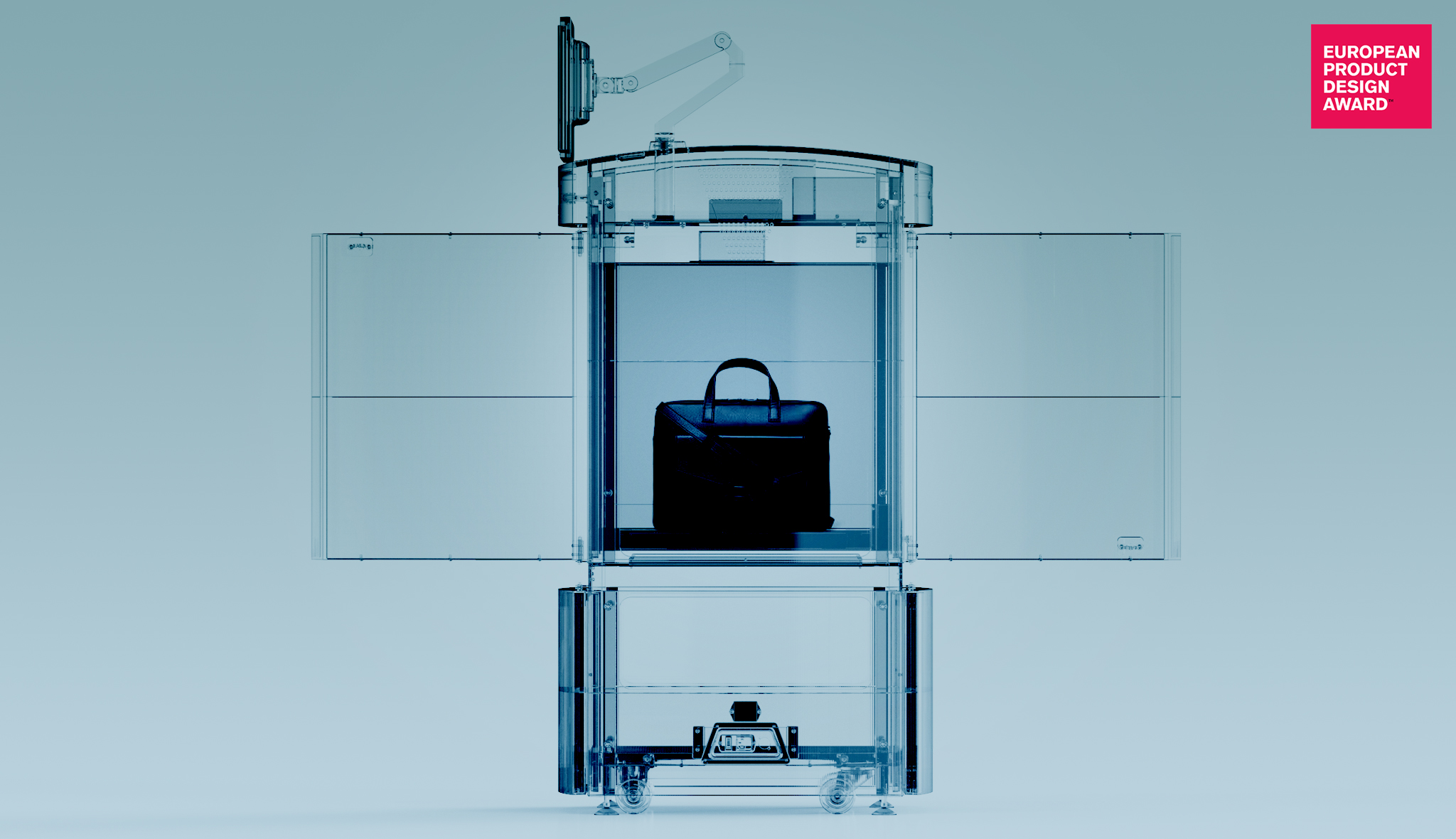

As an award-winning product design consultancy, we provide the same level of innovation in design to all aspects of your project, including the manufacturing process. Your key considerations include timeframes, cost, and consistent quality, ensuring that the last product is as perfect as the first through the production process. Our design for manufacturing service will give you confidence every step of the way. We also offer expertise in providing design for manufacturing services that incorporate an engineering methodology to optimise time-to-market and reduce production costs, helping companies achieve their manufacturing goals and launch new products.

Our design for manufacturing service ensures your product is optimised, ready for launch and beyond.

Design for Manufacturing

The industrial design and development of a successful product is a demanding task, particularly when cost-effectiveness is a priority. Nevertheless, this is where Bluefrog Design excels in the design process.

We carefully engineer your products with consideration for design optimisation. This includes a wide range of factors from materials and assembly to customer appeal and fitness for purpose. For those more demanding products, we will carry out FEA and FMA analysis to ensure the highest possible standards are met. Technical documents and specifications are created to ensure the proposed design intent is effectively communicated to all invested stakeholders.

Selecting the right manufacturing process based on factors such as cost, product material, volume, surface finish, post-processing needs, and tolerances is crucial for the product’s success.

Integrating Design for Manufacturing (DFM) in the early design phases is crucial to optimising time-to-market and minimising production costs.

Our experience and expertise in manufacture and assembly processes means we can introduce them at an early stage in the product development journey to increase efficiency and avoid unnecessary problems. Our Design for Manufacturing (DFM) process ensures your product is fully optimised, ready for launch and beyond in the development process.

Manufacturing Strategy

The quality, life expectancy and performance of a product depends not only on its design, but the assembly process, materials and equipment used in its production, and the manufacturing cost. So, when we’re assessing the viability of your product, we closely examine the demands it will place on the manufacturing process, including the volumes required, maintenance and environmental impact. Sustainable product design forms a vital part of our approach; we consider the 4R’s of sustainability from initial phase through to the end life of your product.

Design decisions made in the early stages significantly impact manufacturing costs, with approximately 70% of these costs determined by these decisions.

We have a proven track record in choosing and approving the right manufacturing method across a range of products and industries. Our designs have cost effectiveness built in and, as part of our manufacturing support service, we include discussions with suppliers and manufacturers early in the development cycle. At all stages we aim to reduce the potential for problems further down the line. Reducing the number of manufacturing operations is crucial for efficiency and cost-effectiveness.

We also analyse different manufacturing processes using Design for Manufacturability (DFM) principles to ensure optimum selection and overall viability.

Sourcing

As an independent product design consultancy, you can be sure we only select manufacturers for your product based on the needs of your business and to ensure high product quality. We’re also able to ensure testing and production trials are carried out correctly and your original vision remains intact.

Meeting testing and compliance requirements is crucial in product development and manufacturing. We emphasize the importance of addressing industry or regulatory standards, securing certifications, and ensuring that the product design is tested for compliance before mass production begins.

Alongside our own industrial expertise, we have an extensive database of suppliers from across the globe. Great product development is about working with the right people; where third-party specialism or technology is needed, we have access to the very best.

This means we can research niche processes and services to find the best match for your product; not only the way your product is made, but also your logistics, flexibility, and corporate social responsibility criteria. We’re here to give you the best information by undertaking cross-comparisons and supplier audits on which you can make important decisions and identify the best route to market.

Supply Chain Management

Our design for manufacturing support service is with you every step of the way, aiming to optimize time-to-market and limit manufacturing process production costs during early design phases. With multiple parties coming together, including experts, suppliers, and manufacturers, we provide a central hub to oversee the project on your behalf.

Ensuring a quality product that meets industry or regulatory standards is crucial. Our project management services include liaising with third parties, identifying timeframes and ensuring targets are met, scheduling, monitoring quality standards, lead-times, and deliveries. We are experienced in meeting required quality standards and obtaining the necessary approvals.

By working with Bluefrog Design as your design and innovation consultants, you can be assured that Standard Operating Procedures are followed and your product will maintain consistent standards throughout the production process, on to the shelf and into the hands of the customer.

Manufacturing

What our clients say about us

We take immense pride in collaborating with industry-leading companies and it's always gratifying to receive testimonials for our dedicated efforts.

View more of our Product Development Services

If you would like to hear more on how we can improve the quality of your products or help with your product development, please contact Bluefrog Design at mail@bluefrogdesign.co.uk

FAQ’s on Design for Manufacturing

Why is Design for Manufacturing Important?

Design for Manufacturing (DFM) is crucial as it significantly reduces production costs and time by ensuring a product is optimally designed for ease of manufacturing from the outset. It aligns design concepts with manufacturing capabilities, facilitating smoother transition from design to production. DFM ensures product quality, lowers manufacturing complexities, and accelerates market entry, ultimately enhancing profitability and customer satisfaction.

Where to Start With Design for Manufacturing?

Starting with Design for Manufacturing (DFM) entails initially understanding manufacturing capabilities and constraints. Engage with manufacturers early, aligning design principles with production feasibility. Thoroughly reviewing designs for simplification and cost-effectiveness is key. Utilising software tools for DFM analysis, and fostering a collaborative environment between design and manufacturing teams, ensures seamless transitions from design to production. DFM is about informed design choices, optimising for both manufacturability and functionality from the outset.

How Does prototyping fit in to Design for Manufacturing?

Prototyping serves as a bridge in Design for Manufacturing (DFM), facilitating real-world testing of design functionalities and manufacturability. It unveils potential production challenges, allowing for design refinements. The iterative process of prototyping and adjusting design according to manufacturing feedback ensures cost-effectiveness and efficiency. Moreover, it fosters better communication between designers and manufacturers, aligning goals from conceptualisation to the production floor, ensuring a smoother transition towards the final product creation.

How Long Does Design for Manufacturing Take?

The duration of Design for Manufacturing (DFM) hinges on the project’s complexity, the level of expertise involved, and the responsiveness of the iteration cycle between design and manufacturing feedback. Typically, it can span from a few weeks to several months. Early engagement with manufacturers and meticulous planning can expedite this phase, ensuring design optimizations align with manufacturing capabilities, ultimately streamlining the transition to production, saving time and resources.

What is DFM and DFA?

DFM (Design for Manufacturing) and DFA (Design for Assembly) are integral facets of product development aiming to simplify product structure and its assembly, reducing manufacturing costs and complexities. While DFM ensures a design is efficiently producible, DFA focuses on easing the assembly process. Both methodologies, when employed harmoniously, expedite the manufacturing cycle, curb expenses, and enhance product quality, significantly bolstering a project’s market viability and cost-effectiveness.

What is DFA in manufacturing?

DFA, or Design for Assembly, in manufacturing, refers to the methodical approach aimed at simplifying product structures and their assembly processes to curb production costs. By focusing on reducing the number of parts and easing assembly operations, DFA facilitates quicker and more cost-efficient assembly, driving down overall manufacturing expenditures while maintaining or enhancing the product’s functionality and quality, thus significantly contributing to a project’s market competitiveness.

What is an example of design for manufacture?

Design for Manufacture (DFM) is manifested in the simplification of a product’s structure while maintaining functionality, to ease production and reduce costs. For instance, using a snap-fit design for a plastic casing instead of screws enables quicker assembly and lowers manufacturing costs by eliminating the need for additional hardware and labor. This strategic alignment of design with manufacturing capabilities ensures cost-effectiveness, streamlined production, and often a faster time to market.

Related Projects

Need help with design for manufacturing?

Socials