From Idea to Reality: An A-Z of Prototypes in Product Design Development

What is a Prototype?

A prototype is an early version of a product that lets designers and stakeholders play with ideas and concepts in the physical world. It’s a tool to visualize and test different aspects of the design brief during the initial stages to ensure the final product is functional and user-friendly. Prototypes are part of the design process, a way to test and refine the product based on user feedback before it goes into production.

Table of Contents

Design Thinking and Prototyping

Design thinking is a problem-solving approach that involves critical thinking to understand user needs, redefine problems, and create innovative solutions to prototype and test. Prototyping is a key part of this process; it’s not just about making a model but about incorporating user feedback through an iterative process to refine and perfect the design.

The Design Process

The process is a holistic approach that involves several stages, starting from concept development and understanding the brief to detailed prototyping and refinement. The initial stages are crucial for self-initiated learning and critical evaluation, allowing designers to sketch and prototype early ideas. Each stage builds on the previous one so designers can incrementally refine their ideas and solutions based on continuous learning and feedback.

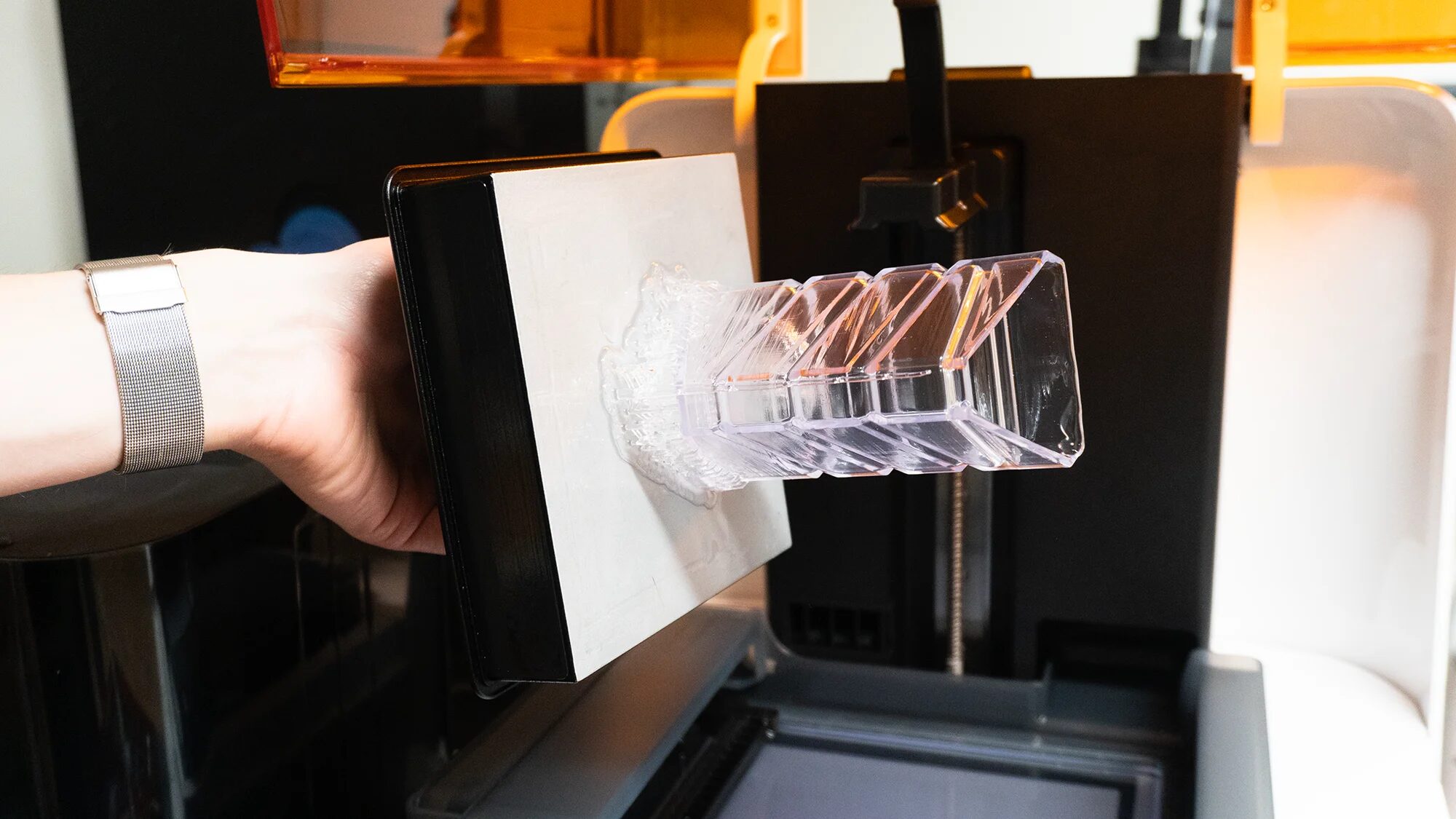

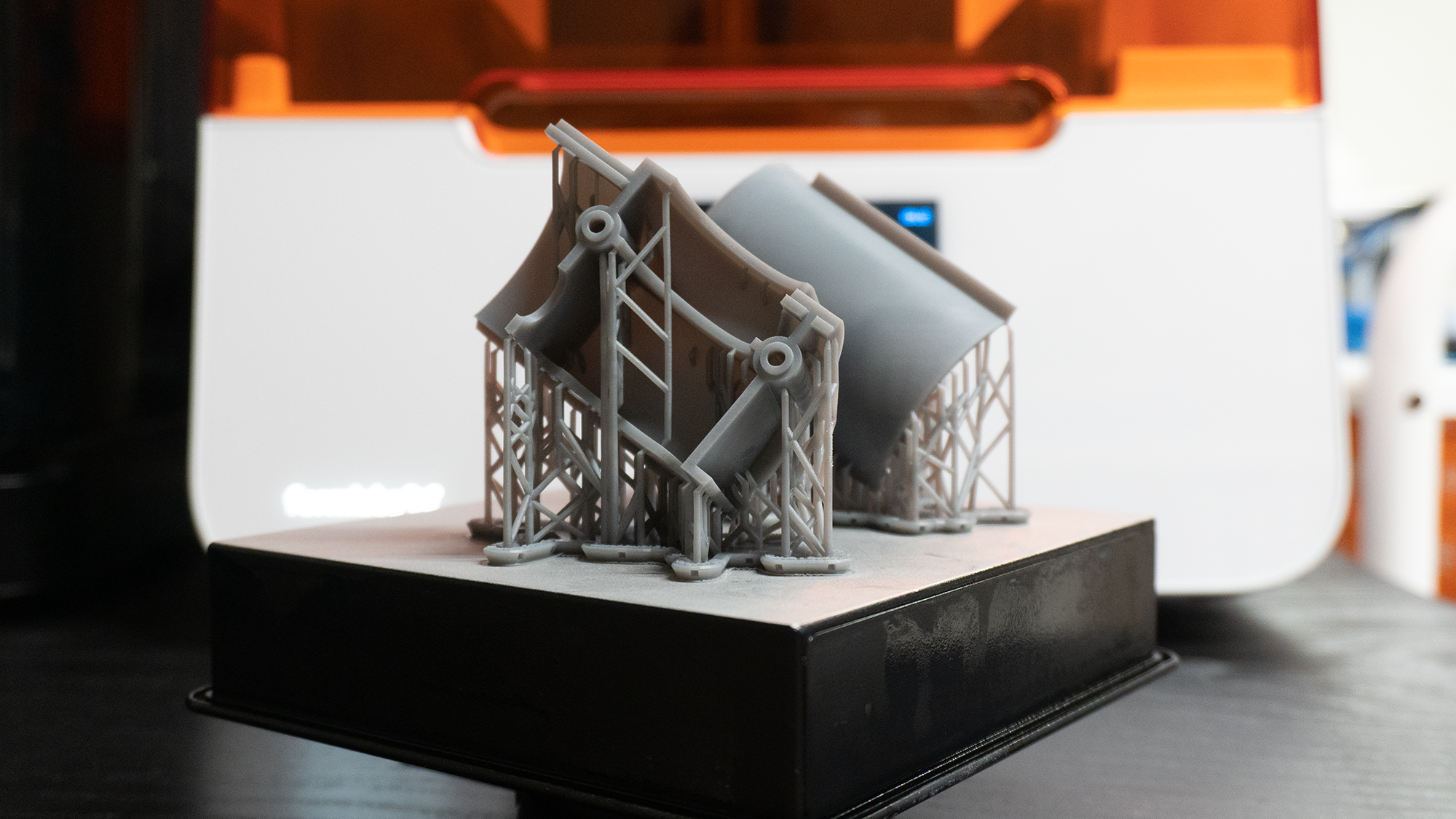

Prototyping Methods

Rapid prototyping is one of the different prototyping methods used during the ideation phase to explore ideas and concepts. Low-fidelity prototyping might be card or paper models to explore ideas, high-fidelity prototyping uses materials and processes that mimic the final product to get a deeper understanding of what it will look and work like.

Why Prototyping

Prototyping is essential as it bridges the gap between concept and reality. During the initial stages, prototyping helps in developing creative solutions and refining ideas efficiently. It allows designers to try out different approaches, conduct user testing, test functionality and make sure the design meets user needs before significant resources are invested in production. This stage is critical to identify potential problems and ensure the final design meets user needs, avoiding costly mistakes down the line.

Manufacturing Processes and Prototyping

Understanding manufacturing processes is key as it affects the design and prototyping stages. Prototyping can give insight into the manufacturing capabilities and production constraints so designers can create more manufacturable and efficient products.

Prototyping Innovative Solutions

Design validation in prototyping innovation leads to breakthrough product ideas. By testing and iterating designs, product designers can explore solutions that might not be obvious, pushing the boundaries of what’s possible within the constraints of modern manufacturing.

Prototypes

Trying out different types of prototypes—functional prototypes, low-fidelity, and high-fidelity—helps designers decide which level of detail is right for each stage of their design projects. Each type serves a purpose, from conceptual models to exact replicas of the final product.

Prototyping Tools and Materials

The tools and materials used in the creative industries can make all the difference to a prototype. From traditional craft materials to digital tools like CAD software and 3D printers, we can prototype any product.

Prototyping Tips

Following best practices for prototyping, including setting clear module aims, is key to success. These include setting clear goals, involving stakeholders early and iterative testing based on real-world feedback.

Common Prototyping Errors

Even experienced designers, including those in a degree programme, can fall into common traps, like underestimating user testing or ignoring the material and scale. Knowing these common mistakes, such as poor material selection, can help teams avoid them and create better prototypes.

Prototyping and UX

Focusing on user experience and user-centric design during prototyping can introduce students to the importance of creating user-centric products, ensuring the product looks good, works well, and is easy to use. This user-centric approach is key to creating products that really meet consumer needs and stand out in the market.

Launch and Refine

The final stages of prototyping include ensuring market readiness by preparing the product for launch and meeting requirements such as English language qualifications for international markets. This stage is critical to make sure the product is ready for market and any last minute tweaks are made to make it a success.

Conclusion

Prototyping is a complex process that requires planning, doing and refining. By understanding prototyping and following best practices product designers can make their innovations practical and marketable. This guide helps designers to get through the product development journey from concept to product.

View more of our Product Development Services

If you would like to hear more on how we can improve the quality of your products or help with your product development, please contact Bluefrog Design at mail@bluefrogdesign.co.uk

FAQ’s on What Product Designers Do?

What skills do product designers in an industrial design consultancy need?

Product designers need a mix of creative and technical skills including CAD skills, material knowledge and an eye for aesthetics and market trends.

How do product designers in consultancies work with others?

They often work with engineers, marketers and UX designers to ensure the product is feasible, meets market needs and is user centric.

What are the career prospects for product designers in industrial design firms?

Career prospects are good, working on many different projects across many industries and often leading to design management or specialisation in specific product types.

Ready to get started on a project?

Socials