Leading the way in Medical Equipment Design.

It’s fair to say that as industrial designers we are inspired by technology. It has brought incredible changes to industry, in our homes and workplaces and, notably, in our hospitals and healthcare. Arguably it’s here, in the medical sector, that constant development of technology has had the largest impact on our modern world, saving countless lives and improving lifestyles around the world.

Table of Contents

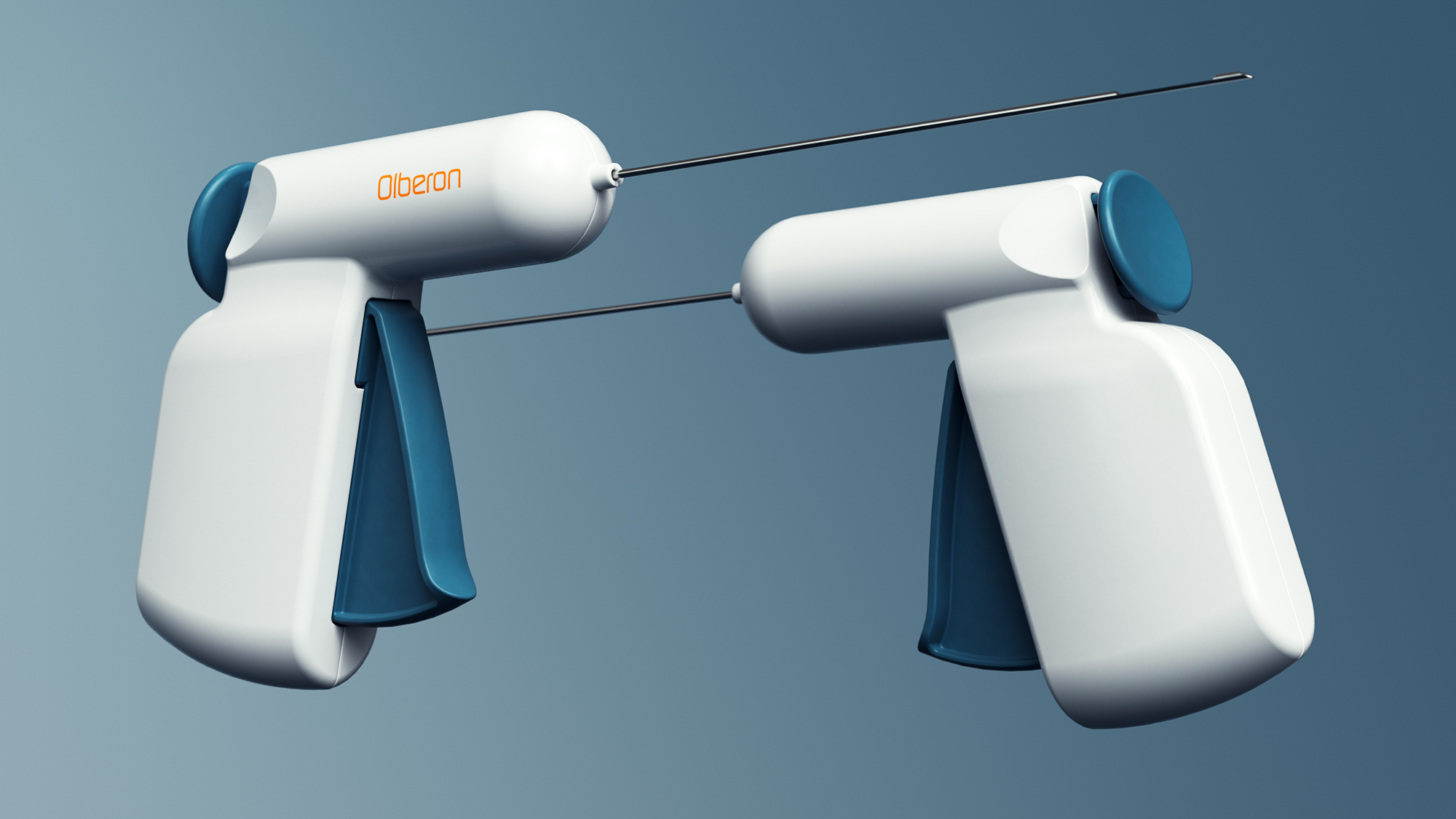

At Bluefrog Design we are very proud of the role we’ve played in bringing new products to the market. Our medical device prototyping services produced a 3D printed chest guard solution – winner of the Advanced Healthcare Award 2018 – may be specific to sufferers of Paraesthesia, but our work with Cinoptics to design the IRIS Virtual Microscope – used to train surgeons in cataract surgery –will help restore the sight of hundreds of thousands of people who otherwise would have never seen again.

However, not everything we develop is meant for a specific end use. We are often involved in experimental design and Medical technology development that tests theory and feasibility at the very beginning of an idea, with untold applications to be discovered – placing us at the forefront of emerging technologies.

Leading the way with Biomedical Design, Research and Development for Medical Equipment

Over the last 11 years we’ve been involved in a number of collaborative projects and feasibility studies, working alongside businesses and universities such as Strathclyde and Oxford University, and funded by bodies like Innovate UK.

Being involved at the start of the journey gives us a unique insight into the capability of new technologies; we can then use that knowledge for future projects that cross industries and products.

For example, we recently worked as the industrial design consultants in collaboration with De Montfort University School of Pharmacy on a project with two purposes – to explore the process of freeze-drying of pharmaceuticals and to be able to create laboratory scale equipment using Through Vial Impedance Spectroscopy (TVIS). The project, BioStaRT, was successful both in the further development of TVIS and in developing an innovative, fully functioning bench top freeze-dryer.

Building on this technology, we are now collaborating with the Centre for Process Innovation (CPI), GEA Lyophil and others on Project Atlas, investigating and testing technology from BioStaRT to measure the freeze-drying process and ensure pharmaceuticals are developed to an appropriate standard for medical use on an industrial scale.

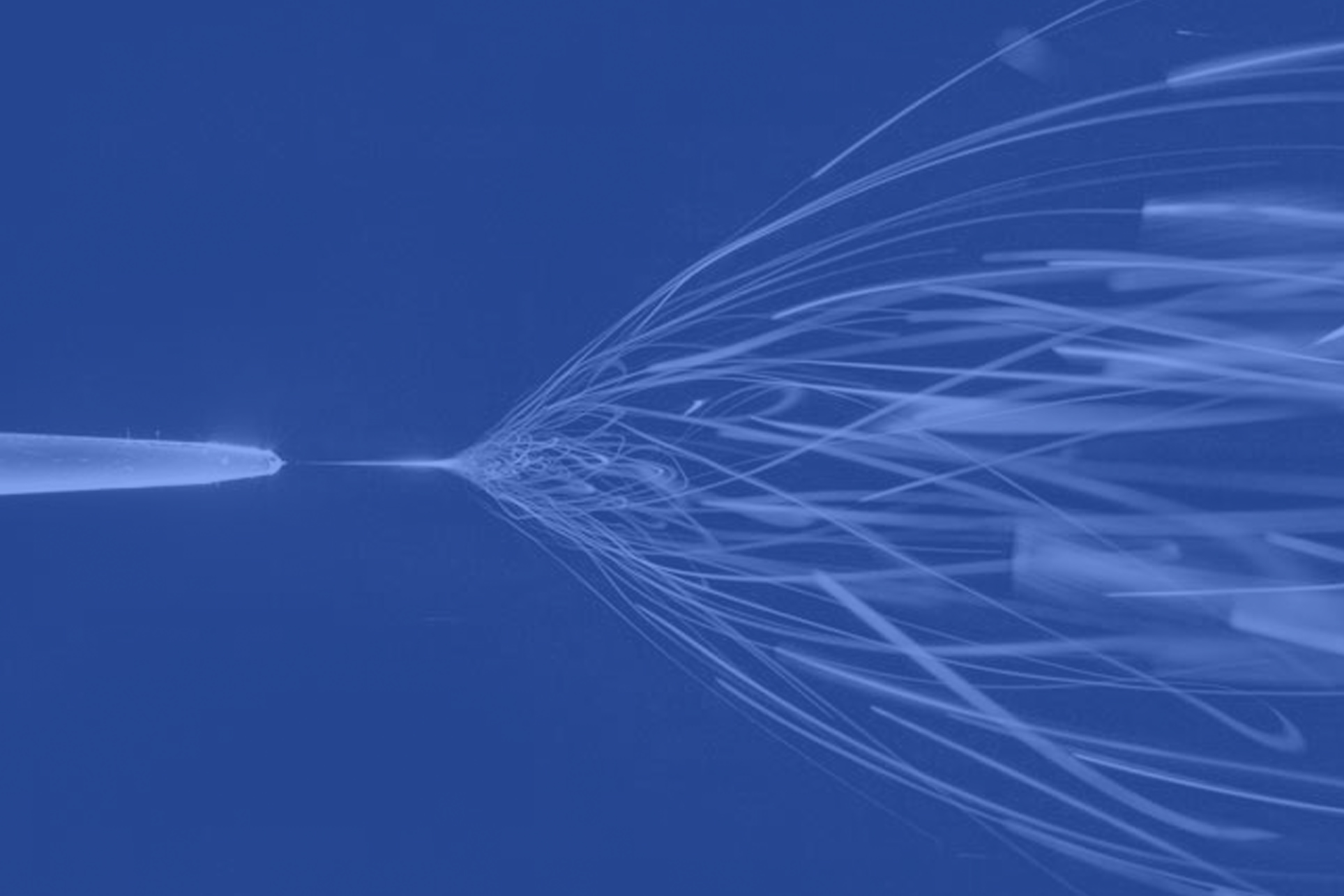

Exploring ElectroHydroDynamic Atomisation (EHDA)

In a new and exciting R&D project, and thanks to EPSRC funding, Bluefrog Design and De Montfort University are exploring the use of EHDA technology and its applications.

The use of EHDA technology allows us to break down a solution and dispense it via precision nozzles to fabricate highly functional micro and nano-scaled structures which can be used for a wide range of medical applications. The process is already playing a major role in the Atlas project.

Our own development in the project may be focused on the physical engineering elements of the delivery system, such as the nozzle technology. However, as part of our commitment we are funding a PhD student to research the various medical applications for EHDA – pharmaceuticals and drug delivery, tissue engineering and regenerative medicine, skin care materials and even food technology.

Bluefrog Design for med-tech design solutions

Innovate design and Technology builds upon itself. The lessons learnt and developments made in one project are then applied to the next. At every stage of the R&D process Bluefrog Design combines experience of proven design with research into emerging technologies. We bring together our knowledge and our intense curiosity to create innovative solutions. And each time we do, we specialise a little more in the medical sector.

R&D projects are, by nature, experimental. They bring together a consortium of specialists from different industries around the world to share ideas and to push technology to the next level. They are fast paced, stimulating and challenging. Through successful collaboration we develop exciting new design solutions, and keep Bluefrog Design a medical device design consultancy at the frontier of emerging technologies.

Why is Medical Equipment Device Design Important?

Medical equipment device design is paramount because it directly impacts healthcare quality, patient safety, and practitioner efficacy. Innovatively designed medical devices can enhance diagnostic accuracy, streamline procedures, and ensure more secure and effective treatments, thereby elevating overall patient care. Moreover, ergonomic and intuitive design aids healthcare professionals in operating the equipment more efficiently, reducing the scope for error, and enabling quicker adaptation to technological advancements. Furthermore, the incorporation of patient-friendly designs can alleviate stress and enhance comfort during medical interventions.

Ultimately, strategic medical device design fosters the seamless integration of technology into healthcare, propelling advancements in medical science while ensuring safety and improving outcomes for both practitioners and patients alike. This holistic approach ensures that devices are not only functionally optimal but also accessible and user-friendly, contributing to enhanced healthcare delivery and patient experiences.

How do Bluefrog Design Develop and deliver Medical Equipment?

Bluefrog Design approaches the development of medical equipment with a rigorous and holistic process that intertwines innovation, functionality, and user-centricity. Commencing with a thorough understanding of both healthcare professional and patient needs, the team engages in meticulous research to underpin the design with relevance and precision. Subsequent conceptualisation is grounded in this research, ensuring the devised solutions are both innovative and applicable.

Leveraging a multidisciplinary team of designers and mechanical engineers, Bluefrog meticulously transitions from concept to prototype, integrating functionality with ergonomic and aesthetic considerations. Rigorous testing phases ensure compliance with medical industry regulations and standards, guaranteeing medical device safety and efficacy. Simultaneously, the team maintains a keen focus on cost-management and manufacturability, ensuring that the medical equipment developed is not only of top-notch quality but is also producible in a manner that is economically viable. This ensures the delivery of medical devices that are not just theoretically sound, but practically applicable and market-ready, enhancing healthcare delivery with thoughtfully designed, compliant, and efficient solutions.

Our Medical Design Services

If you would like to hear more on how we can improve the quality of your products or help with your product development, please contact Bluefrog Design at mail@bluefrogdesign.co.uk

FAQ’s on Medical Device Design and Development

What is an example of a clinical equipment design?

An example of clinical equipment is the Magnetic Resonance Imaging (MRI) machine, which is pivotal in modern diagnostics and clinical settings. Developed in the early 1970s by Dr. Raymond Damadian, MRI machines utilize strong magnetic fields and radio waves to generate detailed images of the structures within the body. This non-invasive imaging technology has been instrumental in diagnosing, monitoring, and treating a myriad of medical conditions, including anomalies in soft tissues, without subjecting patients to ionizing radiation. Its invention marked a significant milestone in medical diagnostics, enhancing healthcare professionals’ ability to explore and understand the internal workings of the body with unprecedented clarity and safety. This innovative technology epitomizes the profound impact that well-designed clinical equipment can have on healthcare delivery and patient outcomes.

How is medical equipment manufactured?

Medical equipment manufacturing is a complex, regimented process that begins with meticulous design and rigorous testing to ensure functionality, safety, and adherence to regulatory standards. Initially, a prototype is developed, incorporating technological, biomedical, and design expertise to create a device that meets both clinical and patient needs. Post-design, the device undergoes stringent testing and revisions to align with regulatory, quality, and safety benchmarks. Once approved, the manufacturing phase commences, involving precision engineering and utilization of appropriate materials, ensuring durability and functionality. Additionally, quality control mechanisms are pivotal throughout the production line to affirm the device’s consistency and reliability. The final stage involves packaging and distribution, wherein the equipment is dispatched to healthcare facilities, ultimately aiding in diagnostics, treatment, and patient care.

What is a medical device engineer?

A medical device engineer specializes in the design, development, and maintenance of medical devices that cater to healthcare and patient needs. Their role encompasses a wide spectrum, involving conceptualizing, developing prototypes, and overseeing the manufacturing of medical devices, while ensuring compliance with regulatory and quality standards. They work at the intersection of biomedical science and engineering, utilizing a profound understanding of biological systems and applying engineering principles to create devices that can diagnose, monitor, or treat medical conditions effectively. This multidisciplinary role often involves collaboration with healthcare professionals, regulatory specialists, and other engineers to ensure the creation of safe, efficient, and innovative medical devices that enhance healthcare delivery.

Like to learn more?

Socials