The Importance of Material Selection in Custom Enclosure Design

What are Custom Enclosures

Definition and Purpose of Custom Enclosures

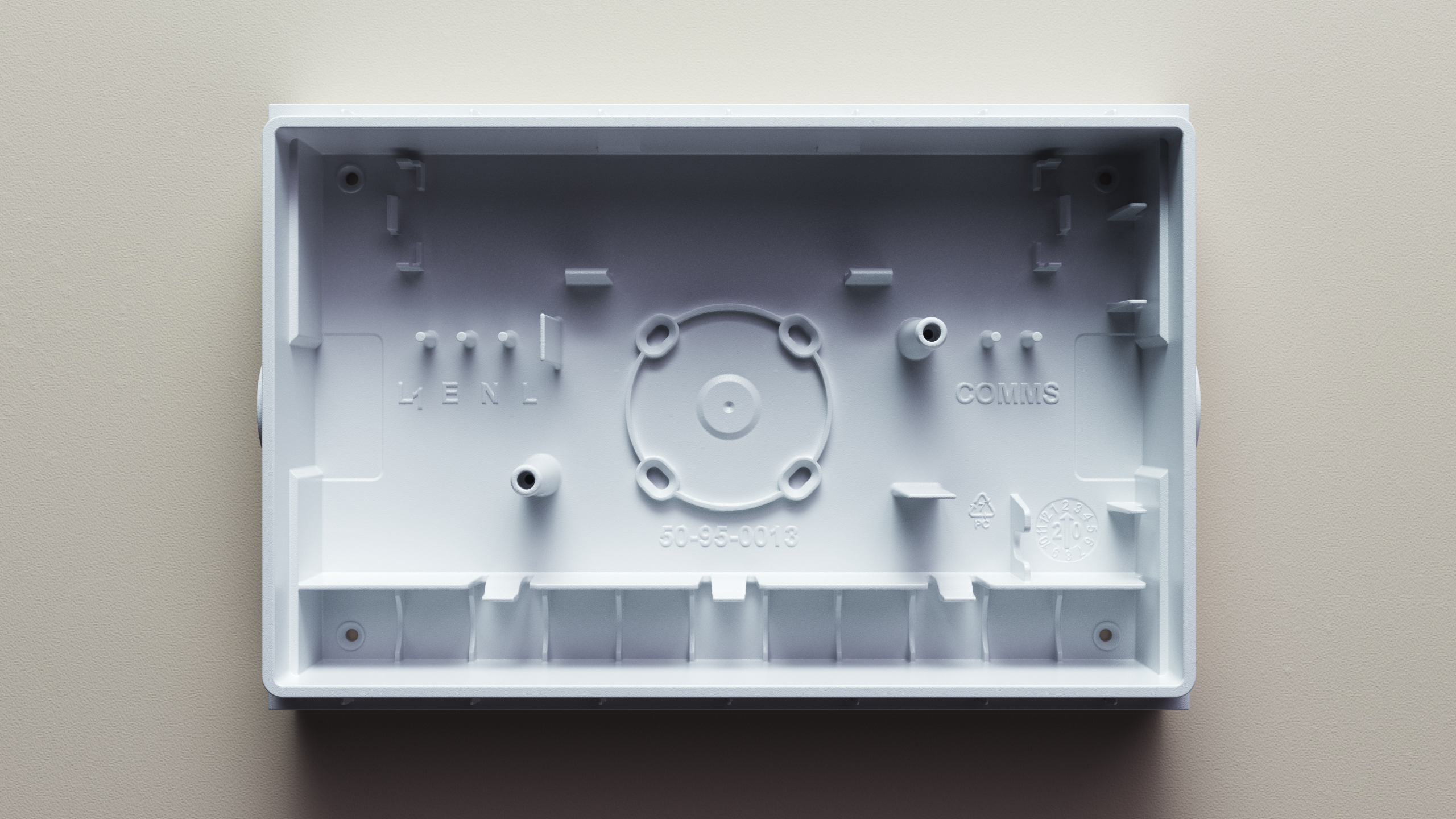

Custom enclosures are bespoke boxes designed to house electronic equipment, control panels and machinery. Standard enclosures may not fully cater for specific requirements of unique applications, custom enclosures are designed to provide maximum protection, security and environmental control for the components inside. This tailored approach is key to functionality and longevity in electronic device design and manufacturing.

Table of Contents

Custom enclosures are created through precision sheet metal fabrication, a process of cutting, bending and assembling sheet metal. This allows designers and engineers to create complex and custom designs that meet exacting requirements and overall effectiveness and durability of the enclosure.

A well designed custom enclosure not only protects internal components but also the overall user experience and product operation.

Design Considerations for Custom Enclosures

Size and Shape Customisation

One of the big advantages of custom enclosures is the ability to size and shape to the exact requirements of the electronic device. Off the shelf enclosures force compromises on size and shape which can limit the efficiency and effectiveness of the housed electronics. Custom electronic enclosure design eliminates these constraints and allows for a seamless integration of electronic components.

This allows designers to accommodate complex dimensions and exact specifications so the final product fits perfectly in the intended space and functionality. Size and shape customisation ensures every enclosure created meets the specific needs of the client and their product. Various shapes of sheet metal enclosures, such as F-shape, L-shape, and U-shape, are often used to house printed circuit boards with connectors, emphasizing the importance of dimensional tolerances and appropriate enclosure shapes to enhance functionality, safety, and manufacturability.

Functional Requirements

Every electronic device has unique functional requirements which can include connectors, switches, displays and interfaces. These must be integrated into the final design of the custom enclosure. Custom enclosures can be designed with precise cutouts, mounting options and cable management provisions so all functional components are accessible and positioned optimally.

The level of customisation available allows designers to create enclosures that not only house electronic components but also usability and accessibility. By understanding and incorporating these functional requirements it’s ensured custom enclosures support the intended operation of the devices they protect.

Performance Requirements for Custom Enclosures

When designing custom enclosures, it is essential to consider the performance requirements of the electronic components they will house. This includes factors such as temperature range, humidity, and vibration resistance. The enclosure must be designed to provide the necessary protection and environmental control to ensure the optimal performance of the electronic components. Additionally, the enclosure must be designed to meet specific industry standards and regulations, such as IP ratings for water and dust resistance.

Material Selection for Custom Enclosures

Suitable Materials

Material selection is key in custom enclosure design as it directly affects durability, moisture and dust protection, and EMI and RFI shielding. Understanding sheet metal gauges and material thickness is crucial as it impacts the strength, weight, and cost of the final product. Choosing the right material is critical for optimal performance in all environments.

High grade plastics and metals should be considered during the design phase. Common materials are steel, aluminum, and stainless steel, each with their own advantages and characteristics.

- Steel is strong and durable for heavy-duty applications.

- Aluminum is light and corrosion-resistant, offering a good balance of weight and structural integrity.

- Stainless steel is environmentally friendly and used in applications where hygiene and corrosion resistance are critical.

Thorough material selection ensures custom enclosures are protected from environmental factors while maintaining high functionality.

Internal Components and Material Selection

Protecting Internal Components

Electronic components are exposed to various environmental factors such as moisture, dust, dirt, heat and physical impact. High quality custom enclosures play a key role in shielding these components from potential threats so they can function optimally and last longer.

Custom electronic enclosures are designed to protect internal components from corrosion, moisture and other environmental challenges. This protection is critical to the performance and reliability of electronic devices over time. By selecting the right materials and designing enclosures that protect against environmental threats we can ensure products continue to operate at peak performance.

Custom Enclosure Manufacturing Process

Fabrication Process for Custom Enclosures

The fabrication process for custom enclosures involves a series of precise steps from raw material to finish. This is critical to create enclosures to exact specifications and quality standards.

The process starts with cutting sheet metal to design specifications. This is followed by bending and assembling the components where precision is key to ensure a perfect fit and alignment. Once the enclosure is assembled it goes through various finishing processes such as welding, painting or coating to improve durability and aesthetics.

A thorough fabrication process ensures every custom enclosure meets quality and performance standards.

Finishing Operations for Custom Enclosures

Finishing operations are a critical step in the custom enclosure design process. The finishing process can enhance the durability and aesthetics of the enclosure, making it more suitable for its intended application. Common finishing operations for custom enclosures include powder coating, anodizing, and silkscreening. These processes can provide a range of benefits, including corrosion resistance, improved appearance, and enhanced durability.

Environmental Considerations

Designing for Environmental Conditions

When designing custom enclosures you need to consider the environmental conditions the enclosure will be used in. For outdoor applications temperature extremes, humidity and UV exposure can have a big impact on the enclosure’s performance and lifespan.

Selecting the right materials and finishes is critical to ensure the enclosure can withstand these environmental challenges. For example plastic enclosures need to be chosen for their UV resistance and thermal stability to prevent degradation over time. Also the design needs to balance performance and cost, so the selected materials provide the required protection without going over budget.

By considering environmental factors during the design phase the final product will function and last optimally no matter where it’s deployed.

Prototyping and Validation Testing

Prototyping and validation testing are essential steps in the custom enclosure design process. Prototyping allows designers to test and refine their design, ensuring that it meets the required specifications and performance standards. Validation testing involves testing the prototype in a real-world environment to ensure that it functions as intended. This process helps to identify any design flaws or areas for improvement, allowing designers to make necessary adjustments before moving into production.

Industry-Specific Applications

Custom enclosures are used in a wide range of industries, including aerospace, automotive, medical, and industrial. Each industry has its unique requirements and challenges, and custom enclosures must be designed to meet these specific needs. For example, aerospace enclosures must be designed to withstand extreme temperatures and vibrations, while medical enclosures must be designed to meet strict hygiene and sterility standards. By understanding the specific requirements of each industry, designers can create custom enclosures that meet the unique needs of each application.

Working with Product Design Consultants for your Enclosure

Benefits of product design consultants

Working with product design consultants can speed up the production process for custom enclosures. They streamline the process so products meet quality standards and are delivered on time.

One of the benefits of working with a product design consultants is in-house design reviews and rapid prototyping. This speeds up the development cycle so you can iterate and adjust based on client feedback. This can lead to cost savings, better product quality and faster time to market.

And product design consultants have expertise in material selection and custom enclosure manufacturing. By leveraging these partnerships you get better design and manufacturing capabilities and deliver great products to clients.

Conclusion

Material Selection in Custom Enclosure Design

Material selection is a key factor in custom enclosure design, durability, moisture and dust protection and EMI/RFI shielding. Knowing the materials available, high grade plastics and metals is critical to performance in different applications.

Custom enclosure design requires material selection to be considered to protect against environmental factors while maintaining high functionality. The right materials not only protect internal components but also the longevity and reliability of the electronic devices.

Material selection is key to custom enclosure projects. By choosing high grade materials and precise design practices custom enclosures can meet the changing needs of clients and last the test of time. By being committed to excellence in material selection and design the company is positioned to be a leader in the custom enclosure industry and ready for the future.

Ready to get started on a project?

Socials